Function Specification

● Nano-scale interpolation accuracy;

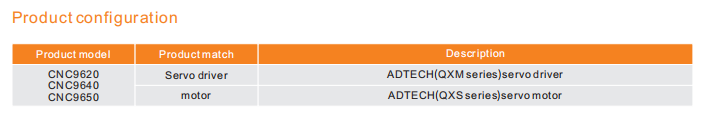

● Can be configured according to different user needs stepping, servo driver, to achieve cost performance;

● Support many kinds of communication methods, like USB, U disk, RS232COM,etc. Easy to help users achieve different data transmission requirements and software upgrades;

● With a network interface, support for remote monitoring and CNC file transfer processing;

● An open platform, can be customized according to customer’s requirements;

● Effect self-diagnosis function, internal and external state of real-time display,alarm immediately if abnormal;

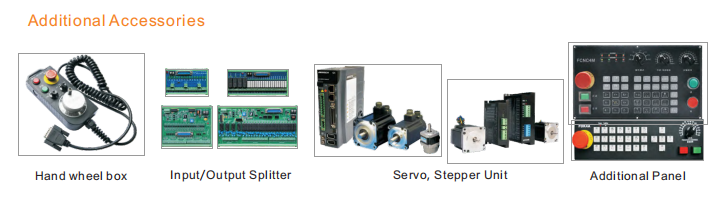

● Support external additional panel, hand wheel box operation, convenient for the customer tools changing ;

● Macro variables, macro definition programming, for a variety of logic relations. Support with parameters of macro program invocation, the user more convenient programming;

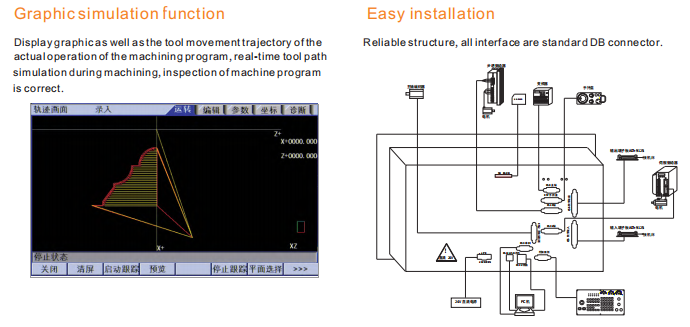

● DXF+G code template function, the DXF automatically converted to G code processing;

● Multiple automatic tool setting methods such as automatic centering and tool setting;

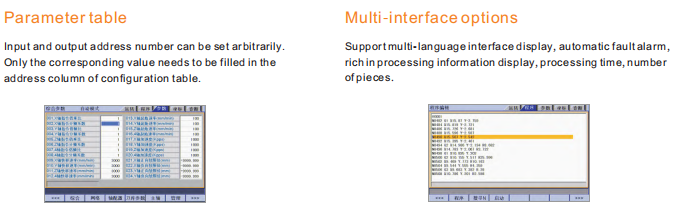

● The teaching function: teaching +RISC programming, using tabular teaching mode, the teaching method is simple,intuitive;

● With communication macro instruction, can read MODEBUS bus peripheral data;

● Support absolute servo systems, the system does not need to return to zero;

● Support Chinese and English, and provide dictionary files. Users can translate into other languages by themselves;